- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

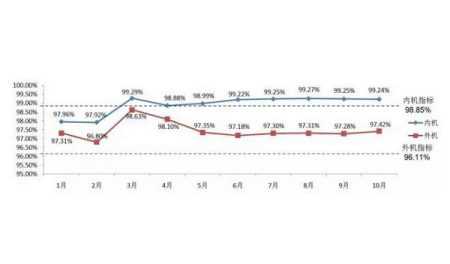

The rolled yield has always been an important parameter in SMT patch. Rolled Yield is the product from the first process to the end of the last process, the main indicators are production quality, work quality, test quality, etc. The rolled yield is a positively correlated ratio with the company’s process capability. If the rolled yield of an SMT processing plant is very high, it also indirectly proves the company’s quality and technical strength. This is why we have always emphasized the need to pay attention to rolled yield internally.

In fact, the rolled yield is more important than the direct reference of a company’s profitability and customer satisfaction. Today, I will share my views above in conjunction with the relevant procedures in the BGA rework.

For example: When BGA is soldered or reworked, there are two important changes in the process of collapse and deformation once or twice. Recognizing and understanding these two processes is very important to the successful soldering or rework of BGA!

It should also be recognized that the heating for rework belongs to local heating, which is different from the one-time welding that is generally carried out with a reflow welding furnace. (1) Melting process of solder joints: two collapses.

(2) Deformation process of the package: the upper bow of the first core part is warped.

The heating and cooling of the rework station is somewhat different from the reflow soldering furnace:

(1) For repairing equipment, since the hot air used for heating is jet air, the flow rate and air temperature are different in different parts. Generally, the core temperature is relatively low (can be tested with paper), and cooling is just the opposite, which is contrary to the requirements of the welding process.

(2) Rework heating or cooling is local heating, not balanced heating like reflow soldering heating. Regardless of PCB or components, the deformation is larger than that of reflow soldering furnace.

The above differences make BGA rework often appear edge or heart bridging phenomenon. BGA welding is already very difficult, and it needs to undergo rework, so the invisibly increasing production process also increases the possibility of abnormal quality. Once there are quality problems in pcba processing, the delivery time and customer satisfaction will be greatly reduced, which will have very serious consequences in the future development of the company.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve