- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

PCB prototype is the early stage of mass production, only an accurate prototype can be carried out in mass production, providing effective PCB files is particularly important, what information needs to be provided to the manufacturer when a PCB prototype?

1: Provide a PCB or GERBER file, which should contain instructions for making the printed version.

2: The substrate required for PCB, the most common substrate for printed circuit boards is FR4, and the main material of FR4 is epoxy resin stripped fiber cloth.

3: The number of layers of PCB board (the number of layers of PCB production is different, the price will be different, and the prototype process of PCB is the same)

4: Solder mask color: There are many colors, you can also choose according to the requirements, the regular default color is green.

5: Silkscreen color: The color of the font and frame printed on the printing board is usually white by default.

6: Copper thickness: The copper thickness is scientifically calculated according to the current of the PCB circuit, and the thicker the copper foil, the higher the production cost.

7: Whether the vias is covered by solder mask: The solder mask is used to isolate the via, otherwise the vias are not insulated.

8: Surface process: mainly plays the role of anti-oxidation, and the conventional default surface treatment process is tin spray plate.

9: The production quantity determines the production cycle, and the production price, the more the quantity, the more affordable the price, the shorter the production time, the higher the production cost.

Small batch PCB manufacturers refer to small batches of processing plants, this kind of factory this biggest advantage of the prototype cycle is fast, for which urgent orders can be directly inserted into the queue production, which is not achieved by large batch factories, the following is to introduce to you a small batch of PCB manufacturers in the process of several important processes!

Drilling: punching holes in the PCB board, wiring needs, to punch a via, structure needs, punching a hole to do positioning or something; Holes in multi-layer boards are not done all at once, some holes are buried in the circuit board, and some are opened on top of the board.

Solder mask: refers to the part of the printed circuit board that needs to be green oil, the professional term is solder mask, and the popular term is green oil

Open window: refers to the part of the printed circuit board that does not need to be green, and it is also the part that needs to be soldered that needs to be exposed.

Tin spraying: This is a kind of surface treatment, that is, spraying tin on the exposed part of the circuit board to protect and solder the role.

Silk screen: The silk screen layer is the text layer, which belongs to the top layer in the PCB and is generally used for annotation. In order to facilitate the installation and maintenance of the circuit, etc., the upper and lower surfaces of the printing board are printed on the required special layer of the logo pattern and text code.

SMOBC: refers to the ink on the copper foil, the understanding here is that we do two kinds of writing process, one is that the oil needs to be printed first and then the surface treatment, and SMOBC refers to the surface treatment first, and then the oil.

Mesh plate: also known as wire mesh, steel mesh or copper mesh; For solder paste printing, SMT (surface mount technology) necessary basic supplies, the purpose is to print solder paste on the PCB, in order to carry out placement and soldering (reflow soldering), the general circuit board factory in the receipt of the customer’s steel mesh information, just the steel mesh and the weld layer comparison, to see whether the weld layer has leakage window, and then the imposition of the plate, to the customer to do the stencil information.

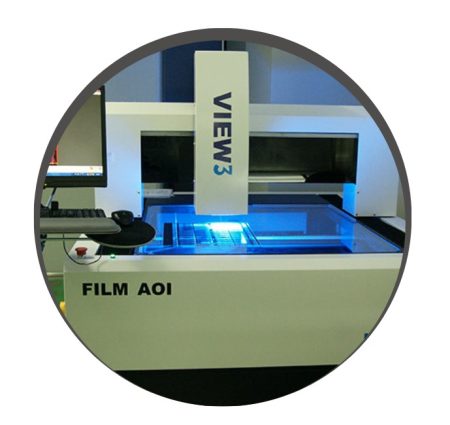

Testing: Manual Visual Testing Manual visual testing is one of the most widely used in-circuit testing methods to confirm component placement on a PCB through human vision and comparison.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

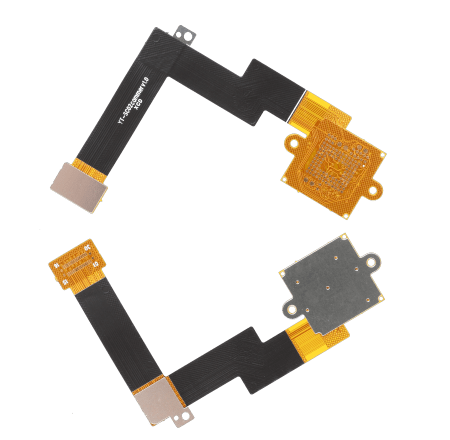

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve