- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

High-density interconnect, or HDI, circuit boards are printed circuit boards with a higher wiring density per unit area than traditional printed circuit boards. In general, HDI PCBs are defined as PCBs with one or all of the following: microvias; blind and buried vias; built-up laminations and high signal performance considerations. Printed circuit board technology has been evolving with changing technology that calls for smaller and faster products. HDI boards are more compact and have smaller vias, pads, copper traces and spaces. As a result, HDIs have denser wiring resulting in lighter weight, more compact, lower layer count PCBs. Rather than using a few PCBs in a device, one HDI board can house the functionality of the previous boards used.

-HDI PCB (1+N+1): Simplest HDI

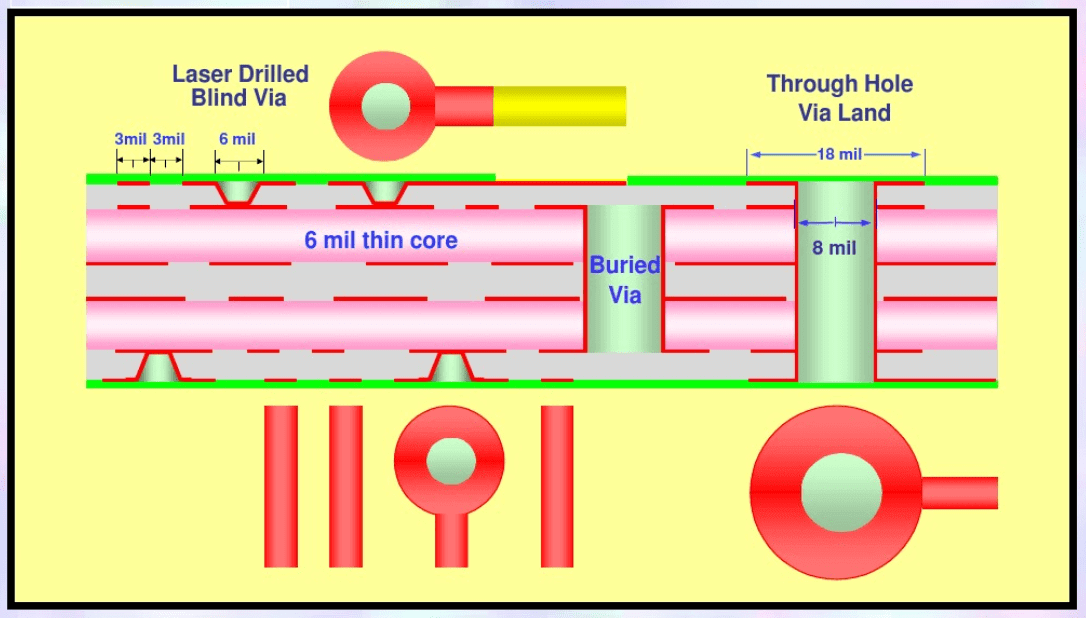

Fig1: 1+N+1 HDI PCB

-HDI PCB (2+N+2): Moderate Complex HDI

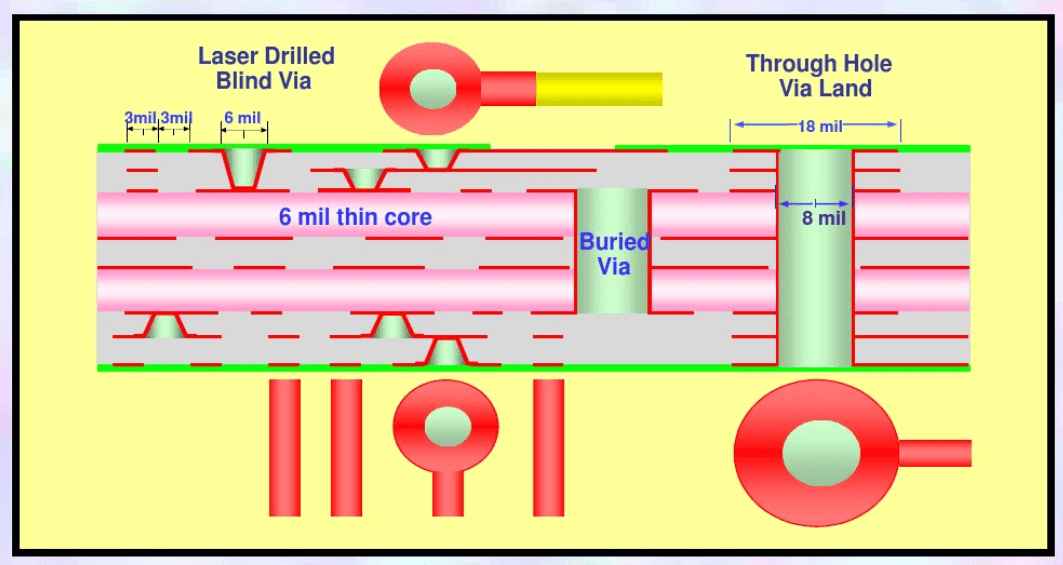

Fig2: 2+N+2 HDI PCB

-ELIC (Every Layer Interconnection): Most Complex HDI

All smartphones are HDI PCBs with ELIC (Every Layer Interconnection) construction. The HDI PCBs are responsible for creating thinner are smaller portable electronic devices.

With the launch of Apple watch and other wearable devices like VR headsets, HDI is becoming the major stakeholder in the consumer market.

The HDI PCB is making an impact on the medical industry. The medical devices are usually HDI since they can fit in small devices like implants and lab and imaging equipment.

As 5G technology is set to jump start since 2020, the demand for more versertile and advanced PCBs grow rapidly. HDI PCB’s super connectivity allows wide employmet of 5G technology become possible.

Like almost everything else, cars are becoming more connected and computerized. Today’s cars have around 50 microprocessors on board that play a role in engine controls, diagnostics, safety features and other conveniences. Many advanced features such as onboard WiFi and GPS, rearview cameras and backup sensors rely on HDI PCBs. As automotive technology continues to advance, HDI tech will likely play an increasingly important role.

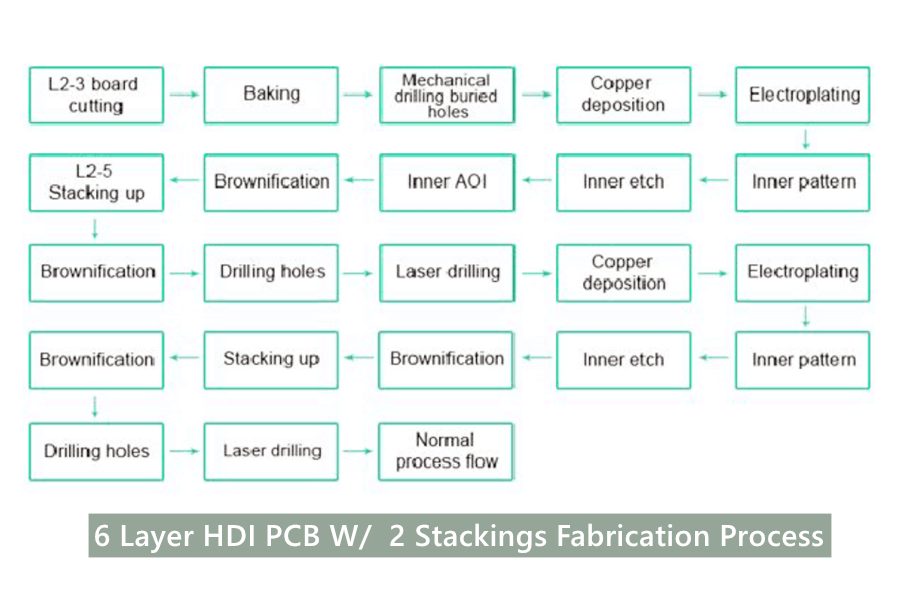

Equipped with up-to-date Laser drilling machine, XPCB is able to cope with most complex HDI structure-ELIC in decent manner, without the high scrappage rate due to conventional mechnical drilling method. We adopt strict quality inspection standards, using IPC-6016, IPC-6011,IPC-6012,IPC-4104, IPC-TM-650 as validating documents. Careful DFM checking will be performed before production. Any suggestion that will help refine the stackup or bring down cost will be updated to customer in details free of charge.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve