- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

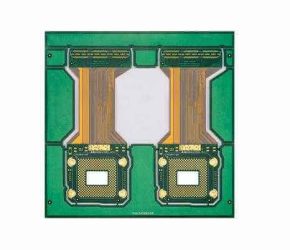

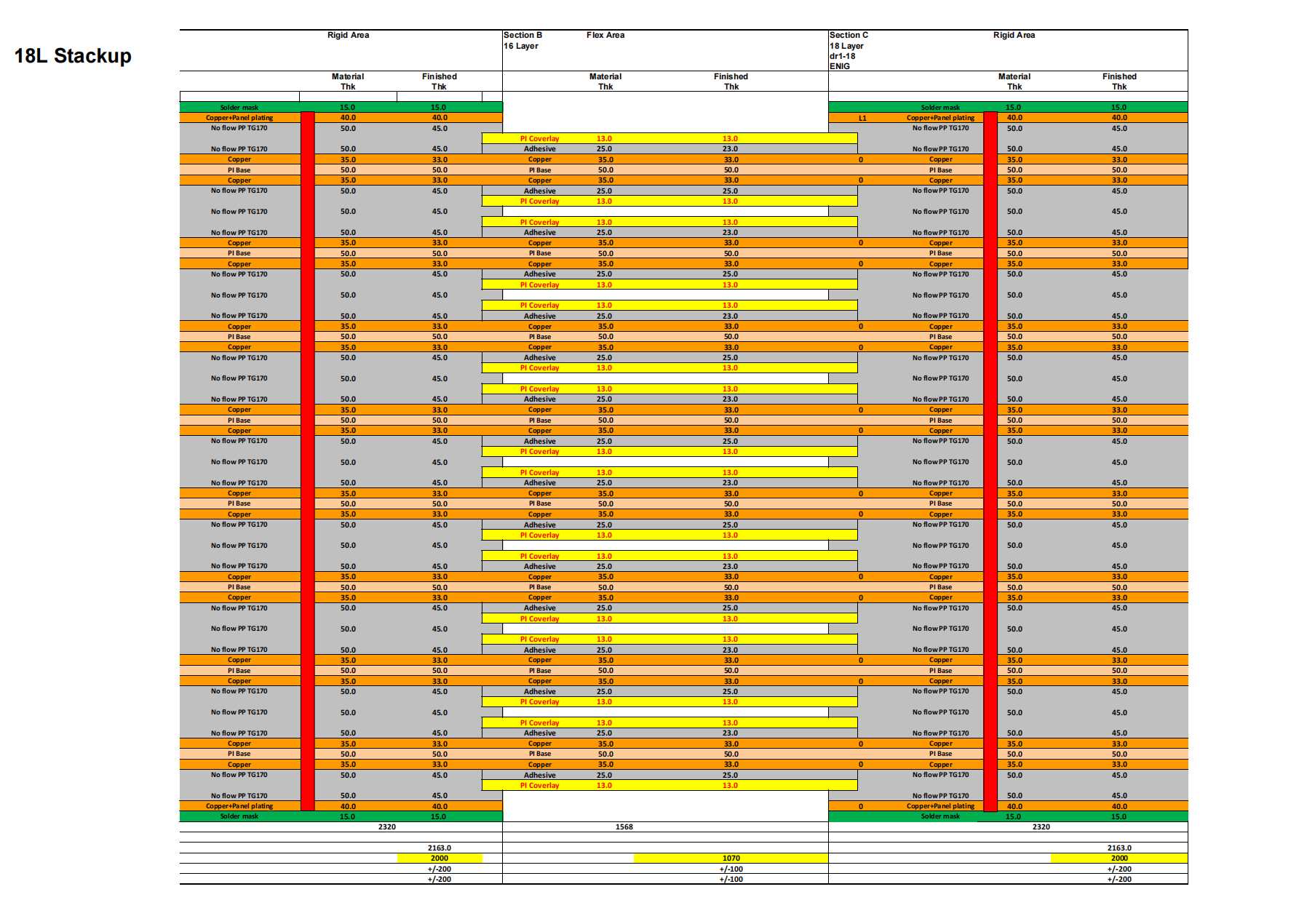

This is a 10 layer rigid flex PCB built by XPCB Ltd, applied in medical electronics. It is with 2R+2F+2F+2F+2R stackup, 2.0mm final thickness. XPCB is a dedicated manufacturer of rigid flex printed circuit board based in Shenzhen, China. We offer QTA, free DRC & DFM checking, turnkey assembly service.

Quick-turn rigid-flex PCB services offer rapid prototype development and production, enabling engineers to expedite design iterations and meet tight deadlines. At XPCB, we bring over a decade of expertise in designing and manufacturing high-quality rigid-flex and intricate flex PCBs. Our proactive approach to Design for Manufacturability (DFM) ensures seamless transitions from prototype to volume production, minimizing delays and defects. With mastery of advanced technologies like VIPPO, HDI, and complex via structures, we deliver tailored solutions that meet your exact specifications and performance requirements.

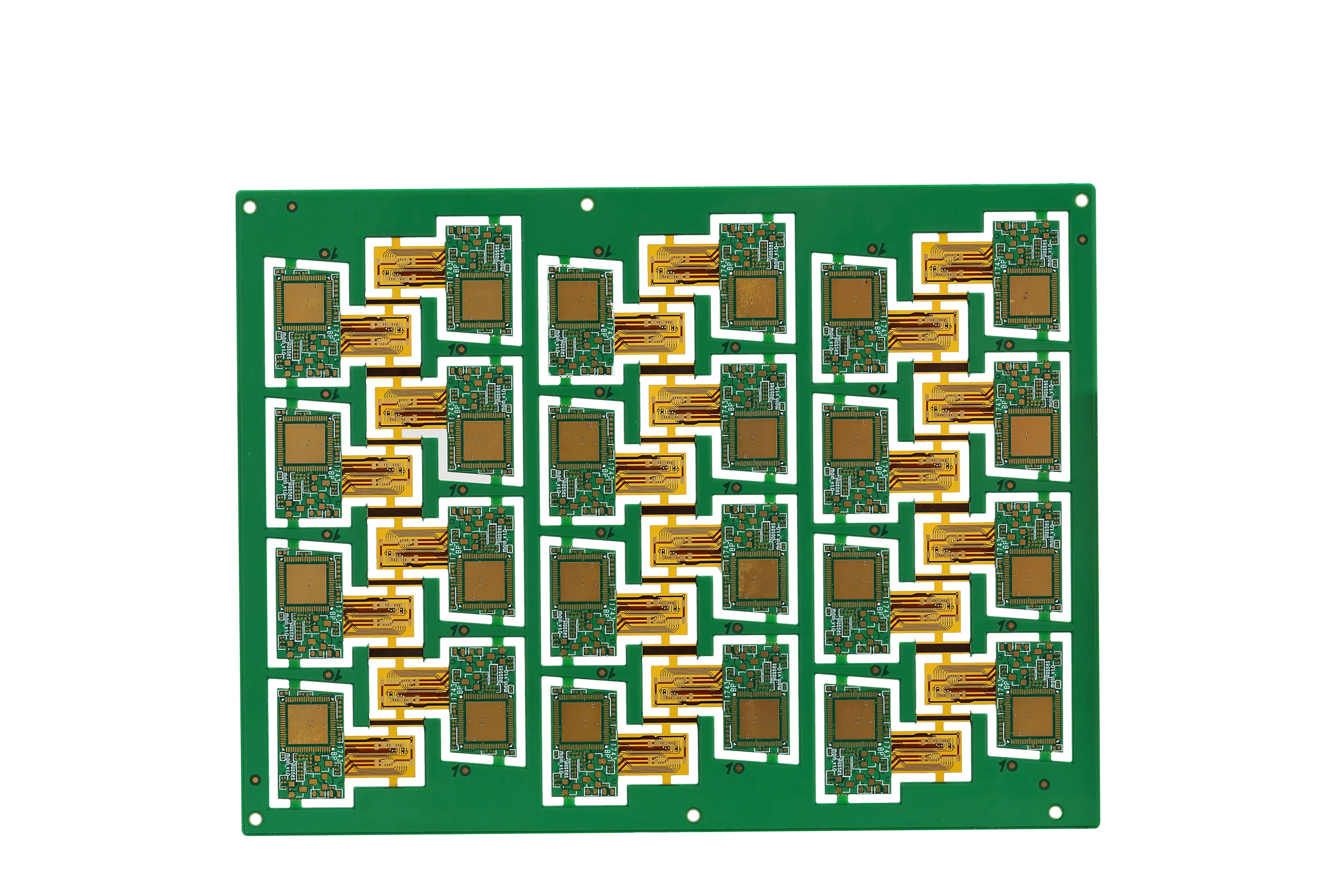

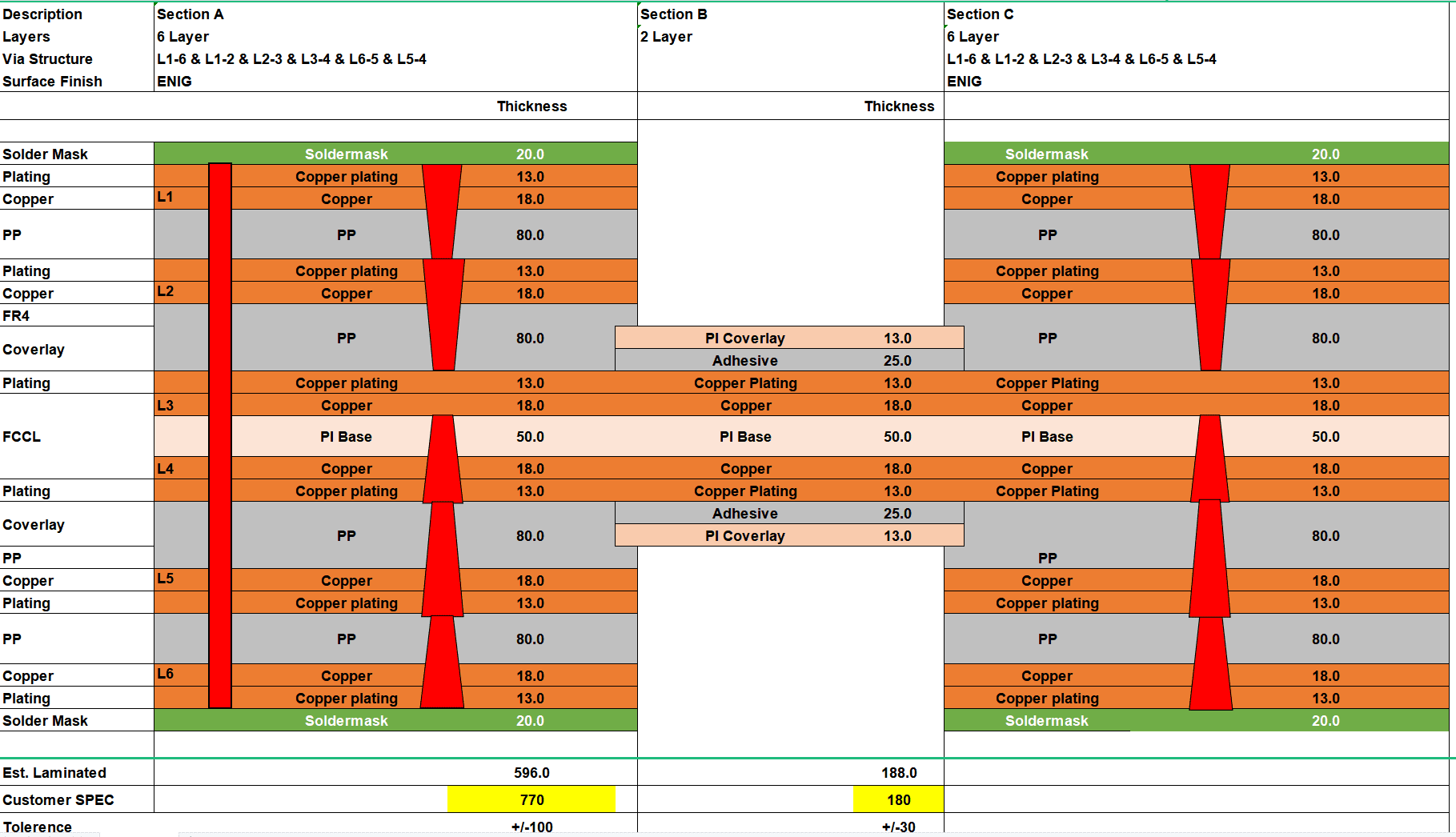

This board is a 6 layer HDI rigid flex pcb. Its overall board thickness is 0.6mm. The finished copper thickness is 2 OZ. Green solde mask is in the rigid area and amber cover film is in flex area.

Lead time: 12 working days

Rigid-flex PCBs are widely used in the medical industry, prized for their enhanced connection reliability and compact size. This 10-layer board serves as an excellent example of this technology’s capabilities:

Stackup Configuration: 2R+2F+2F+2F+2R

(2 Rigid + 2 Flex + 2 Flex + 2 Flex + 2 Rigid)

Key Specifications:

• Final Thickness: 2.0mm

• Minimum Trace Width: 0.075mm

• Minimum Trace Spacing: 0.075mm

• Minimum Hole Diameter: 0.2mm

Lead time: 15 working days

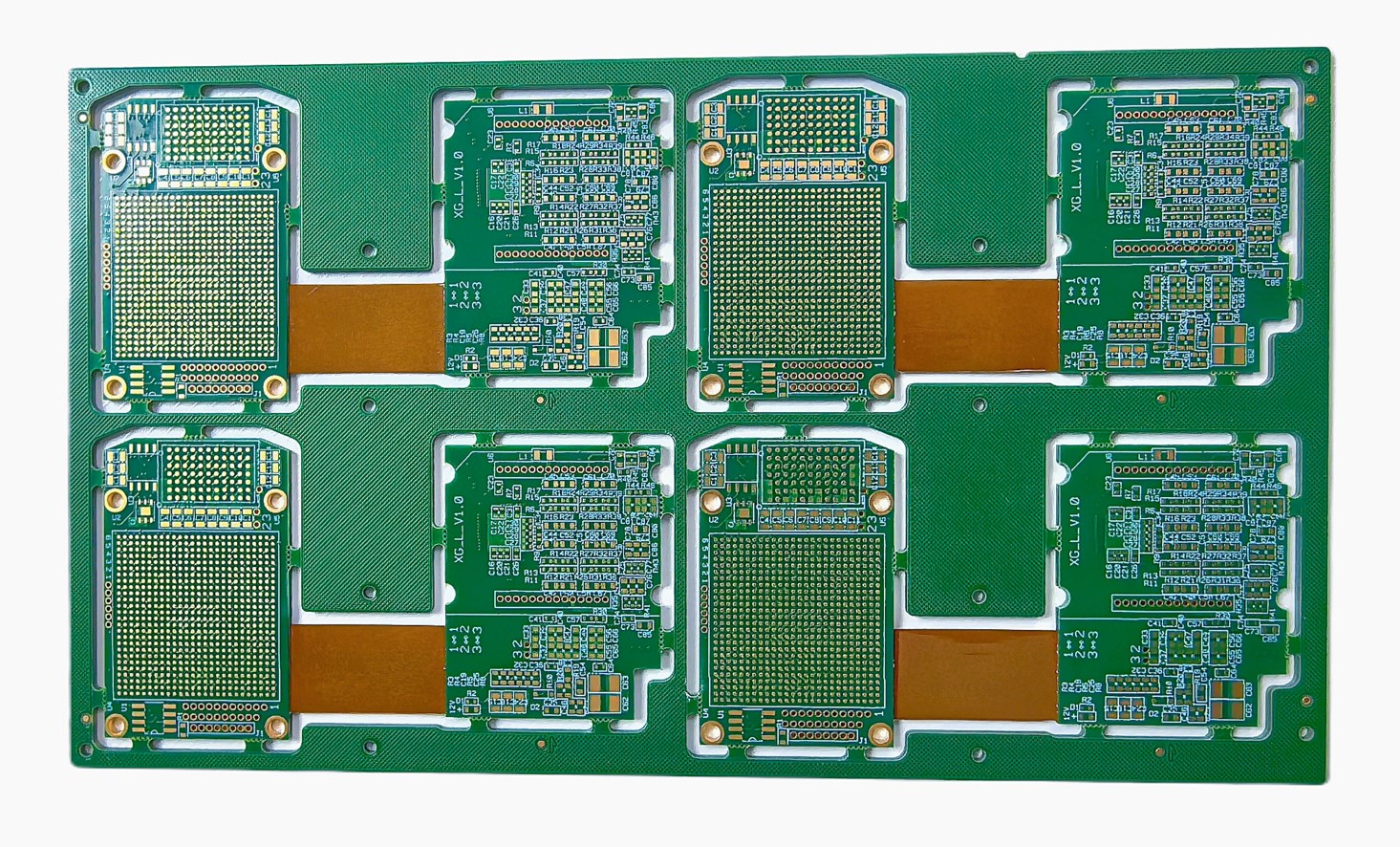

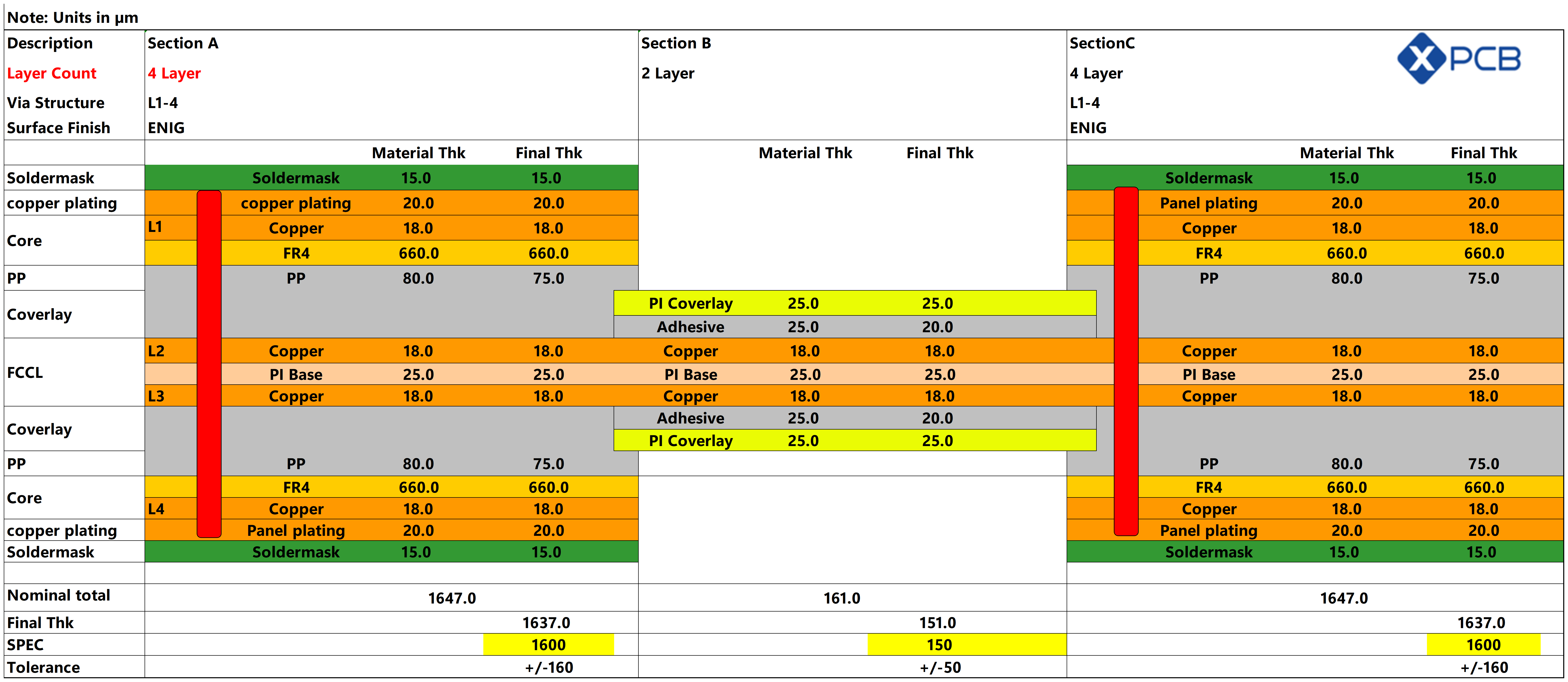

This is a standard 4 layer rigid-flex PCB stackup with through holes design, ENIG finish.

This layer stack is widely used in robotics and automation systems, Wearable devices (smartwatches, fitness trackers), Automotive lectronics (dashboard displays, infotainment systems) etc.

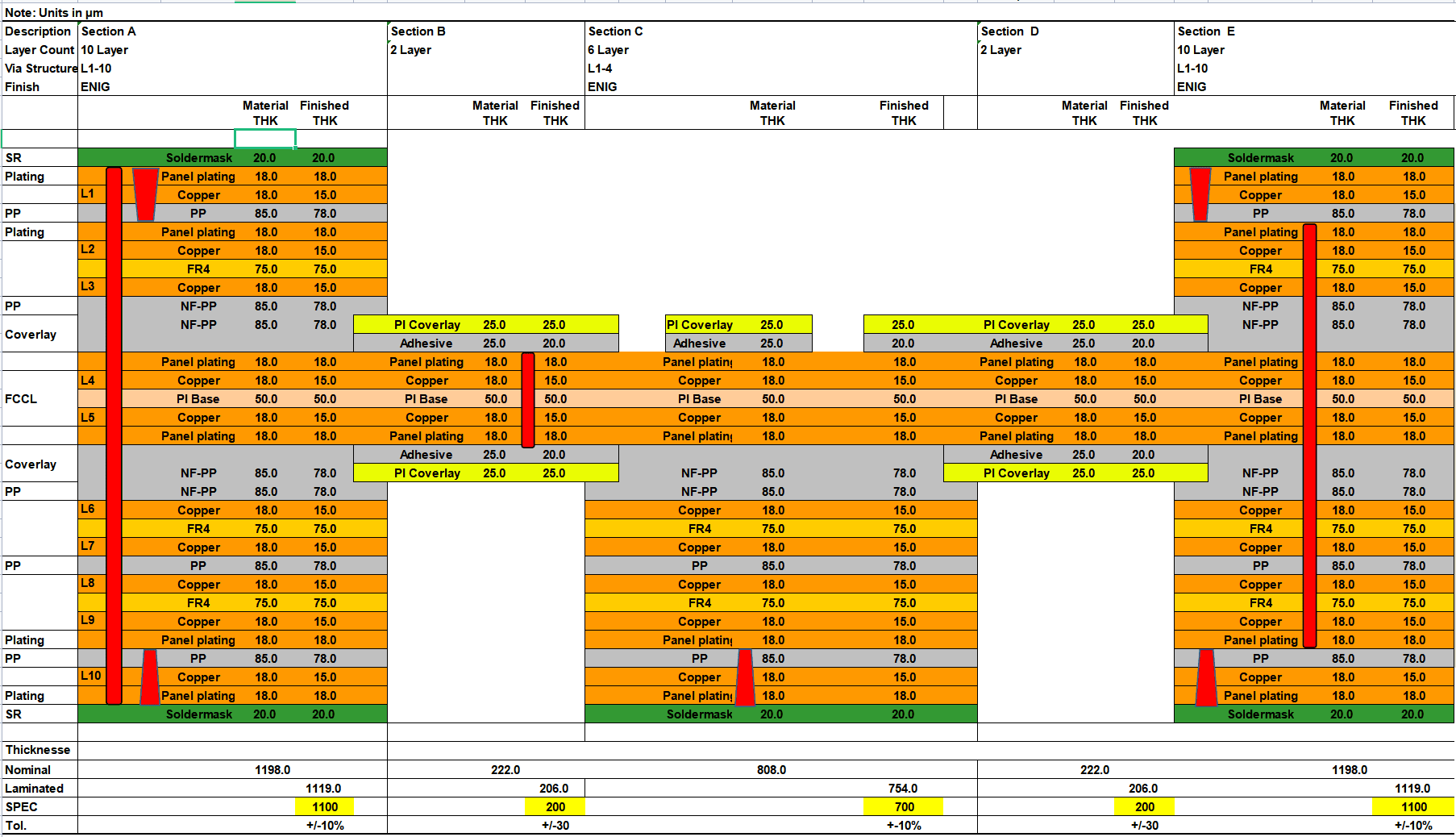

This stackup is designed for electrocardiogram (ECG/EKG) which requires high density interconnection.

Stacked microvias can save space and increase density, offer greater flexibility concerning the inner connections, better routing capacity and less parasitic capacitance.

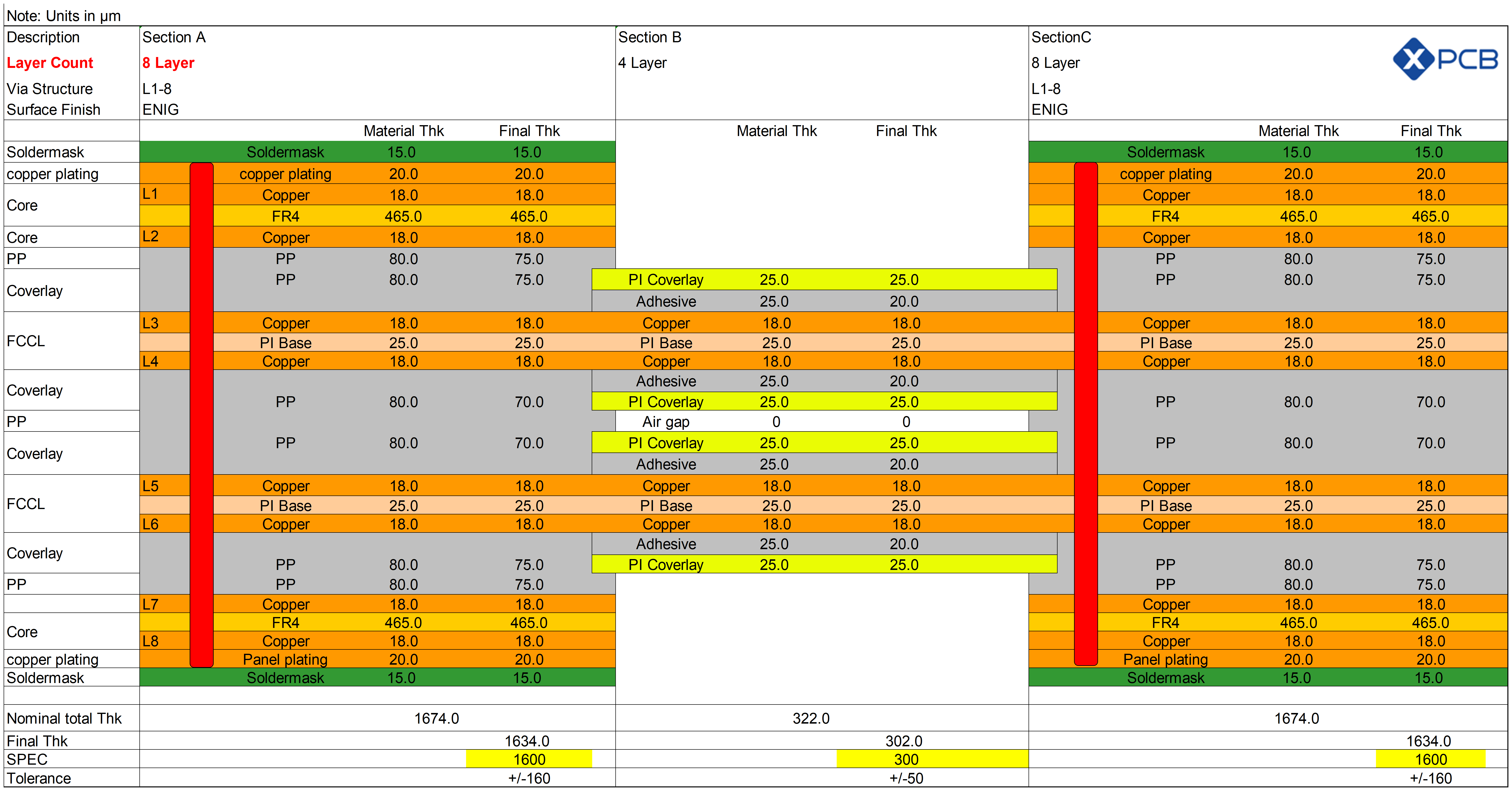

This is a standard 8 layer rigid-flex PCB stackup with through holes design, ENIG finish.

This layer stack is open to customization as per specfic application requirements.

This stackup is created for a 10-layer rigid flex PCB that supports robotics application. It shows all the layer thickness, and drilling placement. There are buried vias in the FPC section and blind vias in the rigid section.

One click to ensure you work on optimal performance, reliability for rigid flex PCB application requirements.

Click Here

Why Clients Choose XPCB for their rigid-flex PCB needs:

Quick Turnaround Times:

Expertise in Complex Designs:

High-Quality Materials and Manufacturing:

Customization Options:

XPCB Ltd has established itself as a trusted supplier of rigid-flex circuit boards, earning the confidence of numerous customers. Our commitment to advanced rigid-flex PCB technology ensures we meet a wide range of manufacturing requirements.

Our specialized rigid-flex circuit team excels in quickly comprehending your designs, streamlining the pre-order process and saving valuable time, especially in cross-timezone communications. As our client, you’ll benefit from:

• Professional Design for Manufacturing (DFM) support at the early stages

• Smooth communication throughout the project

• On-time delivery after order placement

We pride ourselves on our quick-turn rigid-flex PCB service, covering:

• Single-layer rigid-flex circuits

• Double-sided rigid-flex circuits

• Multilayer rigid-flex boards with blind or buried vias

• Capabilities up to 26-layer rigid-flex PCB boards

Our expertise extends to rapid prototyping for concept validation, offering expedited services that balance short delivery times with guaranteed quality. We provide fast, cost-effective “first-build” prototypes to support your innovation process.

For competitive rigid-flex PCB pricing and to work with one of China’s premier rigid-flex PCB manufacturers, contact us at [email protected]. Experience the XPCB difference in your next project.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve